The research focus of the Loo Lab is the design and characterization of next generation polymeric materials that promote sustainability. While the widespread adoption of polymer-based consumer materials has led to global quality of life improvements, polymer scientists are now faced with tackling the grand challenge of reducing our reliance on fossil fuels as well as upcycling the generated polymer waste. In the Loo Lab, the desire to promote sustainability is the motivation behind our research on polymeric materials.

Research in the Loo Lab can be divided into two themes: (1) polymers in advanced manufacturing and (2) polymer-based energy storage devices. In both themes, we synthesize our own materials and characterize them on the nanometer length-scale using a variety of scattering, spectroscopy, and microscopy techniques. We leverage cutting-edge research capabilities at UW-Madison as well as Department of Energy light sources and neutron facilities. Our goal is to develop new structure-property relationships that will lead to the design of next-generation polymer materials with improved properties.

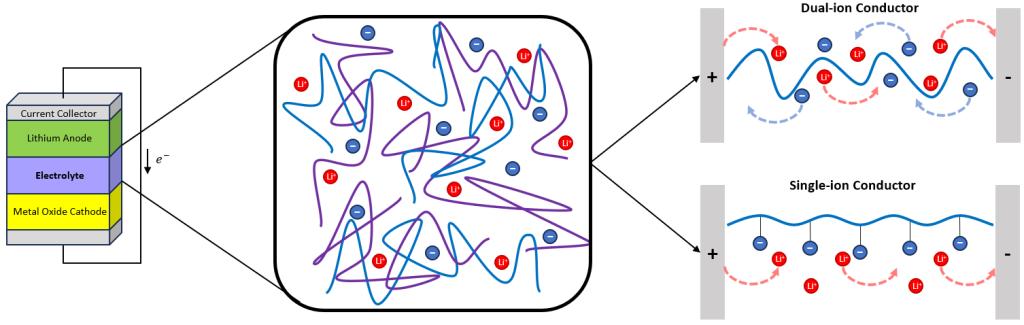

Polymer Blend Electrolytes

The Loo Lab researches polymer blend electrolytes for use in lithium metal batteries. Our aim is to uncover the relationships between structure, dynamics, and ion transport in the polymer blend systems. Through x-ray and neutron scattering we can investigate the structures present in the blends. When coupled with thermal analysis from DSC and impedance spectroscopy, we can obtain insights into the fundamental behavior of the systems.

Funding sources:

Polymer Self-Assembly Below 10 nm for Lithography

Extreme ultra-violet (EUV) lithography tools have arrived at US-based manufacturers and can enable single exposure patterning of features smaller than 10 nm. Polymer self-assembly can be leveraged to improve pattern roughness metrics when the length-scale of self-assembly matches that of the lithographic pattern. The Loo Lab develops novel polymeric systems such as sequence-specific block copolymers, mixed polymer brushes and bottlebrush block copolymers and characterizes their nanostructures with advanced x-ray probes and electron microscopy. We aim to uncover fundamental knowledge that links polymer molecular structure to their resulting self-assembled hierarchical structures to improve patterning outcomes for semiconductor and microelectronics manufacturing.

Funding sources:

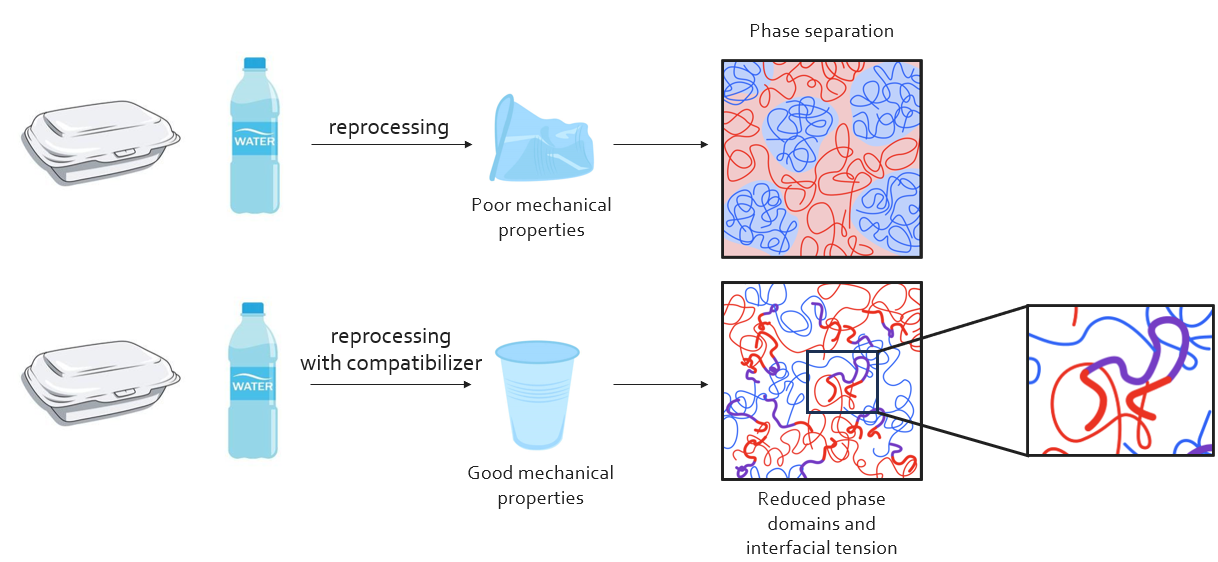

Copolymer Compatibilizers

Our research on block copolymer compatibilizers aims to improve the properties of polymer blends that result from mechanical recycling of mixed plastics waste. By synthesizing multiblock copolymers with specific reactivity and polarity, we can study the performance of these copolymers as compatibilizers in incompatible polymer blends. We aim to uncover fundamental relationships between the chemical and physical properties of copolymers and the mechanical properties of the resulting compatibilized blends to inform strategic design of compatibilizers for next-generation mechanical recycling.

Funding sources: